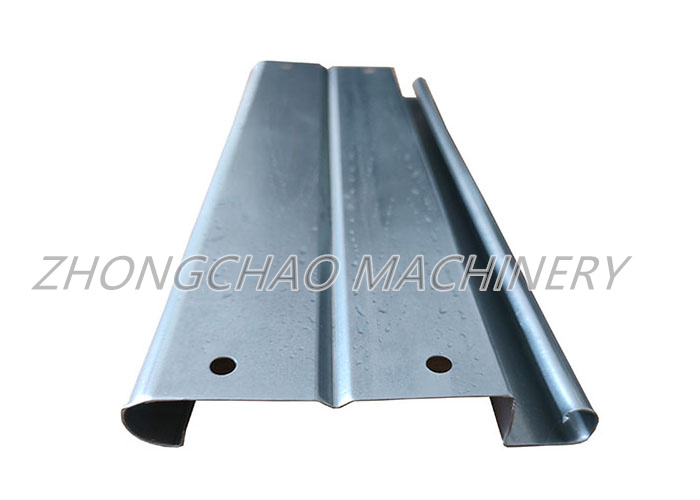

Iso Roller Shutter Door Roll Forming Machine Profile Customized

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Standard Configuration:

Packing Method

Main machine is packaged with plastic film

Transportation

All machines need one 20 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

Warranty

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

FAQ

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- About the after-sales service. We can send technician to your country to fix the machine. The buyer should bear all the cost including: visa, Roundtrip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

The warranty is one year. and we will provide the technical support for the whole life. It is free to maintain the machine the first year after buying, including changing the main components. The first year hence, you will pay for our technician $50 per day to maintain the machine. And the components are not free, if you need to get it from us.

E:- Any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

Our Services

b.Without visiting, we will send you user manual and video to teach you to install and operate.

other necessary things.

After Sevice

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Suitable Material

Material

Galvanized Sheet

Width

140 mm

Thickness

0.7-0.8 mm

Material of rollers

High grade 45# forged steel, surface hard chromium plating

Rows of rollers

12 stations

Material of shafts

High grade 45# forged steel

Diameter of shafts

50mm

Material of blade

Cr12 Heat Treatment

Speed

8-12 m/min

Total power

4 kw

Voltage

380V 50HZ 3Phase

Appearance size (About)

4600mm*800mm*1500mm

Electronic control system

PLC +Touch Screen

3 tons Manual decoiler

1 set

Main roll forming machine

1 set

Hydraulic pump system

1 set

PLC control system

1 set

Receiving Table

1 set

Spare parts

1 set

A:- What service can you provide before order?

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine,and also train your workers/technician face to face.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series