High Rib Glazed Tile Roll Forming Machine Hydraulic Cutting Mode

1. Know about our machine

The roof tile roll forming machine production line includes manual decoiler, main body of roll forming machine, hydraulic cutting system, PLC control system and discharge table. The users can set order as per their requirement to produce the special pieces and length products. This machine line can work automatically by PLC control system. It is easy to operate and running stably.

PLC control system provide automatic working program, client can set all the datum in the hand touch screen, then machine will produce the tile length and quantity according to your requirement.

Features of tile press equipment: The equipment has the advantages of operation, maintenance, maintenance, mechanical debugging, and easy mold replacement.

2. Specifications of the roll forming production line

High grade 45# steel, processed by CNC lathe, Quenched and tempered treatment,

It has the advantage of slowing down before cutting, to

ensure thelength accuracy(±1mm, far better than industrial

standard ±3mm).

3. The advantages of the machine

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 15 years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 30m/min;

5). Very easy to install and operate the roll forming machine.

4. Our company profile

ZHONGCHAO specializes in producing and designing each kind of roll forming machine such as roll forming machines for metal roofing tiles, wall panels. While consummating the old model, with the continuous efforts of our scientific researchers, our company developed one after another of Automatic Cutting and Punching C-type Steel Roll Forming Machine, Automatic Cutting and Punching Z-type roll forming machine, the production line of Glazed Tile Roll Forming Machine, Automatic Panel Machine, Guardrail Forming Machine, Shutter Door Forming Machine, which have the advanced technical level.

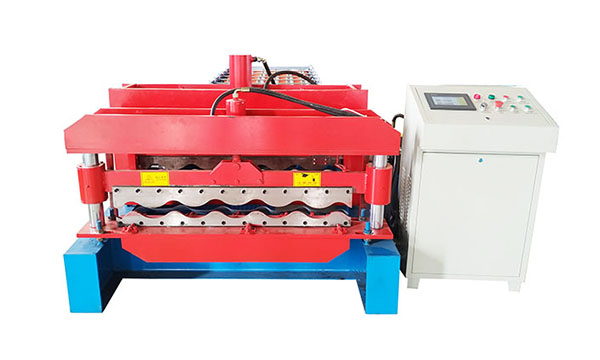

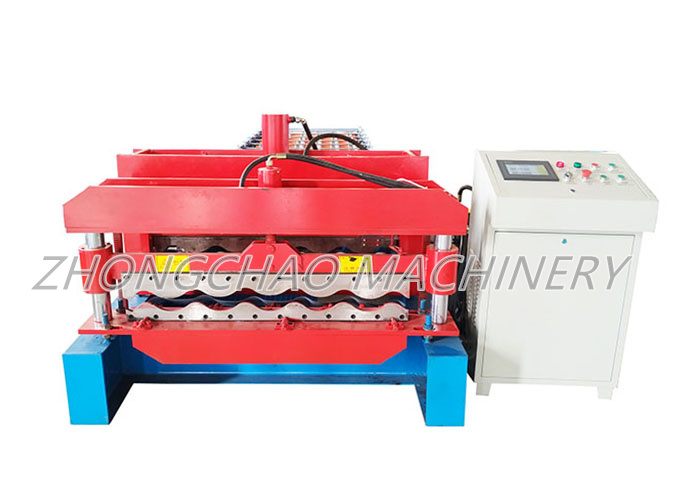

5. Some machine pictures for your reference

Name of Roll Forming Machine

Metal sheet glazed tile roll forming machine color steel tile roofing production line

1

Suitable raw material

PPGI/PPGL/GI/GL Steel Coils

2

Thickness of coil sheet

0.3-0.8mm

3

Feeding Coil width

1200mm

4

Effective width

980mm

5

Under frame

350H steel frame

6

Diameter of Soild shaft

75mm, high grade 45# steel

7

Roller

8

Thickness of middle plate

16mm

9

Forming stations

15 stations

10

Drive type

By chains

11

Power of main motor

5.5kw, Lichao, Shanghai

12

Power of pump station

5.5kw, Lichao, Shanghai

13

Forming speed

About 3-5m/min

14

Hydraulic cutting

Controlled by PLC

15

PLC

Mitsubishi, Japan

16

Material of cutting blade

Cr12Mov, quenching 58-62℃

17

Frequency converter

18

Switch

CHNT

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series