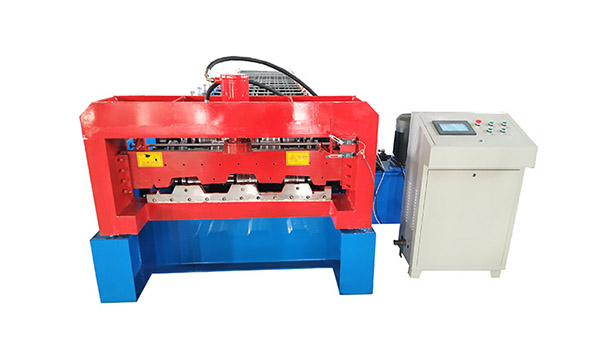

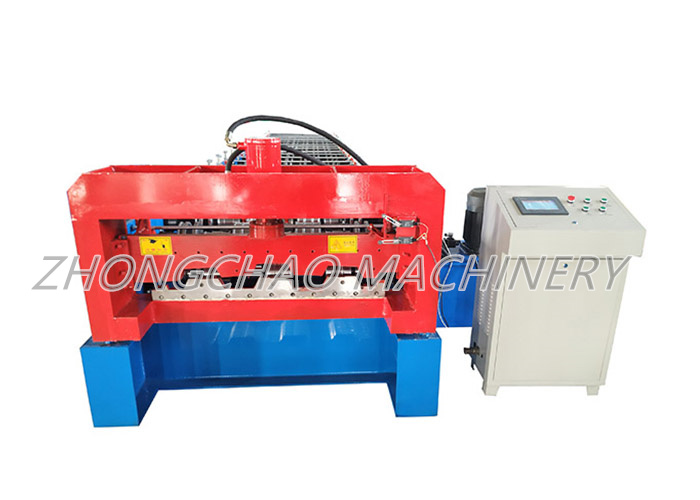

Galvanized steel roofing floor deck roll forming machine

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters:

| Suitable Material | Material | GI, PPGI, PPGL |

| Width | 1220 mm | |

| Thickness | 0.8-1.2 mm | |

| Material of rollers | High grade 45# forged steel, surface hard chromium plating | |

| Rows of rollers | 24 stations | |

| Material of shafts | High grade 45# forged steel | |

| Diameter of shafts | 90mm | |

| Material of cutting blade | Cr12 Heat Treatment | |

| Speed | 15-20 m/min | |

| Side plate thickness | 20 mm | |

| Chain size | 2 inch | |

| Total power | 22 kw | |

| Voltage | 380V 50HZ 3Phase | |

| Appearance size (About) | 12000mm*1800mm*1700mm | |

| Weight(About) | 13 tons | |

| Length measurement | Encoder | |

| Control mode | Delta PLC | |

| Operating mode | Button +Delta Touch screen | |

Manual Decoiler

| Capacity | 5T |

| Inner Diameter | 450-550mm |

| Width | 1250mm |

Steel Deck Roll Forming Machine

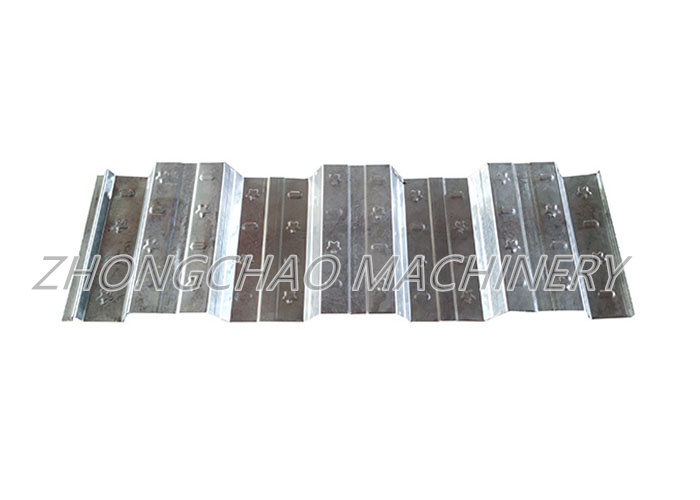

In short,Roof decking floor profiles are typically used as the structural component. The steel decking floor is a cold-formed steel sheet. Metal Decking use in roof and floor systems for supporting the concrete or insulating membrane of a roof. Its design and construction magnify properties of the steel.

Q: Can you customize the machine from your company?

A: Of course, we can manufacture the machine according to your customized size demand.

Q: How is the quality? Is there any department related to quality control?

A: All raw materials we use are quality controlled. Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q: Is the packaging form?

A: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q: How about after-sales service?

A: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp. and many more Two-year warranty and parts replacement.

FAQ

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

Q: What size decoiler can you supply us with?

A: From 5-ton decoiler to a 25-ton motorized hydraulic decoiler.

Q: How to visit your company?

A:a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Q: What can you do if the machine broken?

A:Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

We can provide floor deck roll forming machine for building a big construction, we provide accuracy rollers to satisfy reinforced rib of floor deck, satisfy the customer’s requirement of hardness of floor deck, solve the problem of loading capacity of each floor.

We have many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, and nationally recognized high-tech enterprises. China's three major steel and building materials equipment factories.

The products mainly include trapezoidal steel roof panel/wall panel machine, C&Z type purlin machine, highway guardrail machine, sandwich panel production line, deck forming machine, CUL light keel machine, shutter slat door forming machine, cutting machine, downspout machine, gutter Machine, etc.

We have professional team to make different kinds of roll forming machines for our customers, from designing, processing,assembling, debugging, delivery. We can send our technicians to customer's factory for installation, and teach customer's workers how to use the machines. If there is any problems happened to the machine, we will provide solution at once. Hope we could establish win-win business relations in the soon future!

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series