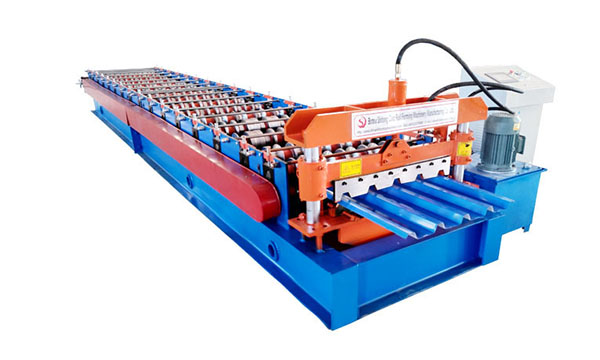

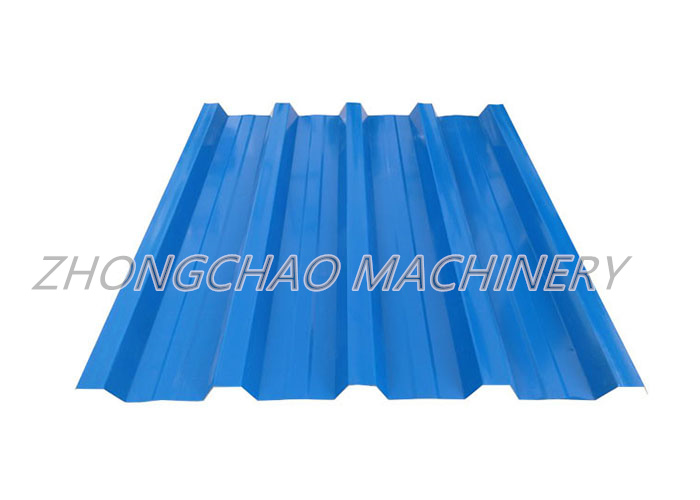

Galvanized Color Sheet Panel 686mm Roofing Roll Forming Machine

1.Application

The roof tile roll forming machine is widely used in industrial and civil architecture, warehouses, large span steel structure housing the roof, walls and interior and exterior decoration and so on.

Characteristic

The machine has lightweight, high strength, color-rich, convenient construction, earthquake, fire, rain, long life, maintenance-free characteristics.

(1) The roof tile roll forming machine using a high level of automatic control software, production information management.

(2) The entire unit automation control system uses highly integrated network, enabling superior performance automation systems.

(3) The pressure-watt machine also has the operation, maintenance, maintenance and mechanical commissioning mold advantages of easy replacement.

2.Equipment For Process Flow

Consist of Decoiler, Main roll forming machine, Cutting device, Hydraulic drive system, Electric control cabinet, ect.

3. The roll forming machine details:

Hydraulic cutting Power

380V, 50HZ,3 phases

1.2 inches single chain

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

coil width

1250mm

efficiency width

1060mm

Material Thickness

0.3—0.7mm

Production speed

20-25m/min

Roller Stations

13stations

Roller material

45# steel, coated with chrome

Maim Motor Power

7.5kw

4kw

Material Of Cutting

CR12 with quench treatment

Hardness

HRC58-62

Tolerance

+-2mm

Electric Source

Also can satisfy customer’s require

Control System

PLC with touch screen

Way Of Drive

Cut-off tool: Use of high strength wear thicker type mold, it is advantageous to avoid cutting off at deformation.

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series