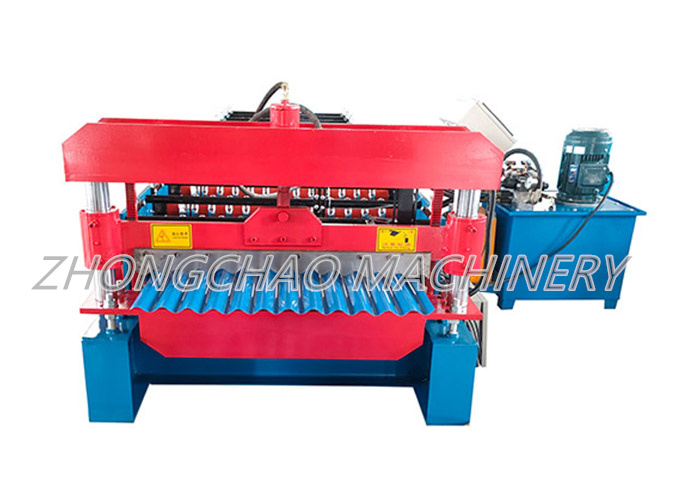

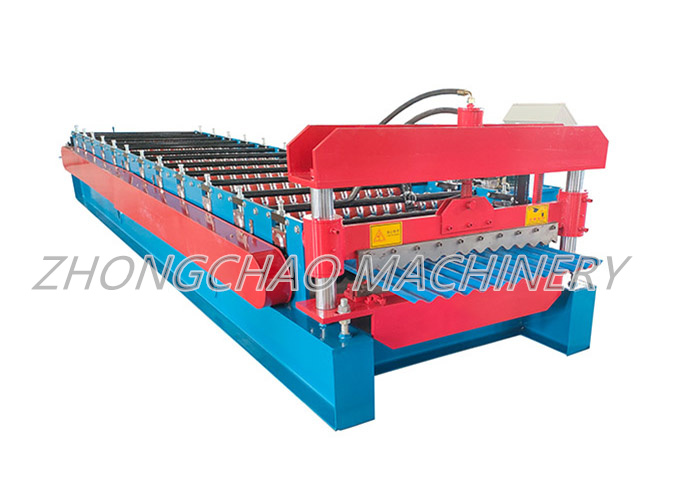

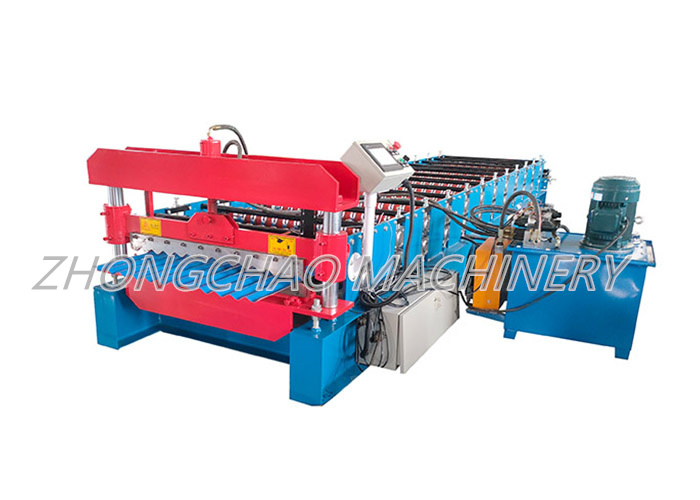

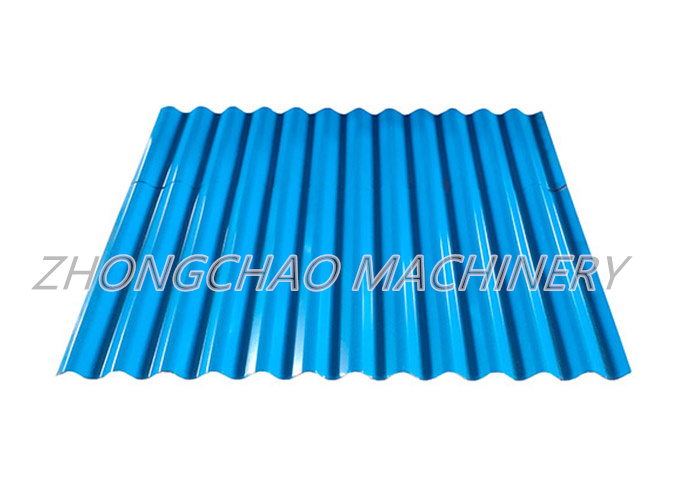

1. Instruction of the corrugated sheet roll forming machine

This roofing sheet roll forming machine is one most popular type of roll forming machines. It makes different shape of color steel roof sheet, which is used for buildings roof, factory, supermarket ect. For this machine, it suit coil width is 1000mm, thickness range is from 0.3mm to 0.7mm. We adopt 16mm thick wall board type to make machine frame strong. Usually it can run with the max speed to 15m/min, PLC with touch screen operation make the machine simple and easy for usage.

2. General parameters of the production line

| Raw material | |

| material | colored steel sheet, galvanized steel sheet, aluminum sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 914mm / 1220mm / 1250mm |

| Efficiency width | 695mm/750mm/1000mm/1050mm |

| Machine details | |

| roller material | high grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | high grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm |

| main frame | 300 H steel |

| forming steps | 15 stations |

| productivity | 25m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| appearance size | 6700mm*1500mm*1500mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirement |

| Cut Mode | Hydraulic forming after cutting off |

| Cutter materia | Cr12 Heat Treatment |

| Electronic control system | PLC, Touch Screen, Encoding counter |

| Color | Blue, green or yellow or as your requirement |

| Rolling material | 45# steel,roller surfaces polishing, hard plating |

| Service life | 10 years |

1>. Free technical support and free accessories supply.

2>. Engineer available to service machinery overseas.

3>. One year warranty is provided.

4>. Long life technical guidance for free.

5>. We always offer technical support, quick response, all your inquire will be replied in 24 hours.

3. roll forming machine company profiles

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. FAQ (about our roll forming machine)

1).What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

2):How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

3):How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month, replace the hydraulic oil every 1-2 years.

5. Roll forming machine pictures for reference:

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series