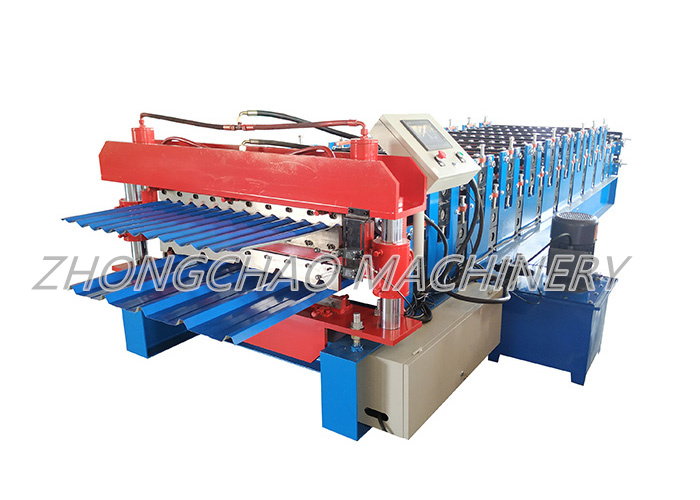

Double Layer Roofing Sheet Roll Forming Machine

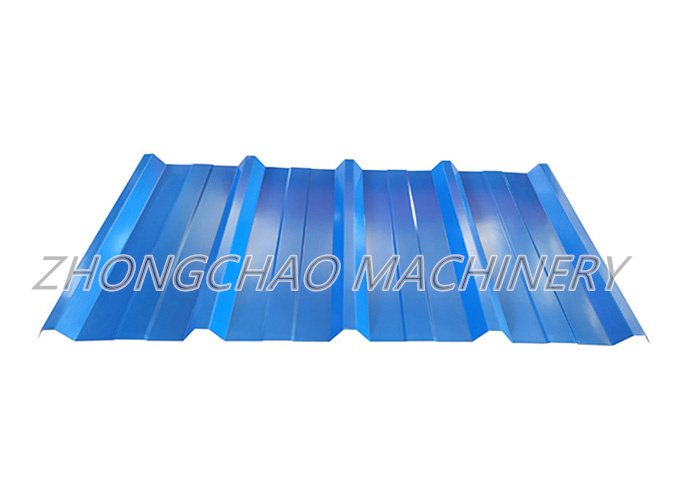

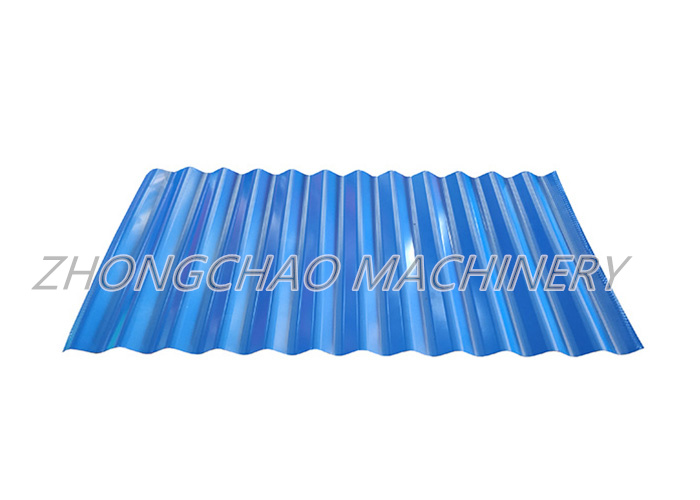

Double layer roofing tile machine: can produce two type sheets, one corrugated sheet and one IBR sheet. The input material are both 1200 mm width with thickness 0.3-0.8mm. Machine speed 20-25 m per minute. With pre-cutting device and double inches chain. This machine cheaper and stable.

We can also supply you the PPGI and GI coils. We know some good supplier. We can put the coils with the machine in the same container.

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters:

1. Machine Specifications

1

Power Requirement

Standard Configuration:

Packing Method

Main machine is packaged with plastic film

Transportation

All machines need one 40 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

Warranty

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,shutter door machine, floor decking machine and other associated equipment. Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

1

Coil Type

Pre-painted coil,Galvanized steel

2

Width

1000mm

3

Thickness range

0.2-0.6mm

4

Yield stress(mm)

Q235

5

Effective width

870/900mm

Voltage

(380V 50HZ),or according client require

Main Motor power

5.5kw

Cutter power

5.5kw

2

Forming speed

10-15m/min

3

Forming stations

900:11row axis 870:13 row axis diameter 70 axis

4

Main Frame

300H beam

5

Sidewall thickness

14mm

6

Forming shaft diameter

70mm 0.01mm-0.03mm(Grinding)

7

Chains

1inch chain drive

8

Type of cutting

Roll formed and length-set cutting

9

Control system

PLC control

10

Install dimension(depend on the final design)

7.3m×1.2m×1.3m

11

Total weight (Approx)

5T

12

Roller

High grade 45# steel, hard chrome plated

13

Feeding system

Guide type

14

Cutting blade

Cr12

15

Frequency changer

Delta

5 tons Manual decoiler

1 set

Main roll forming machine

1 set

Hydraulic pump system

1 set

PLC control system

1 set

Receiving Table

2 sets

Spare parts

1 box

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series