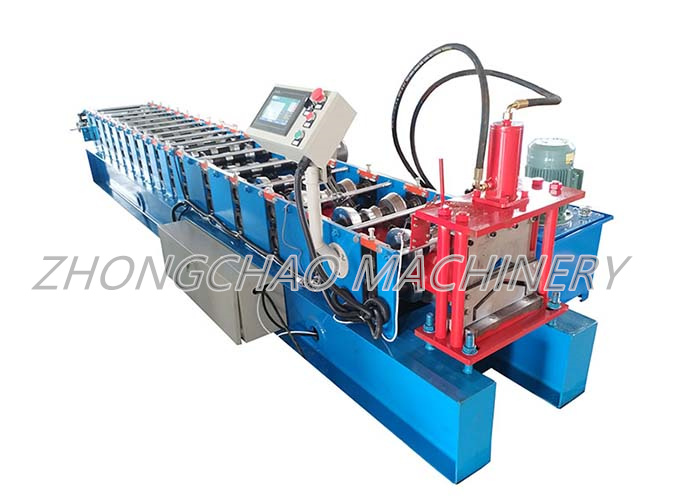

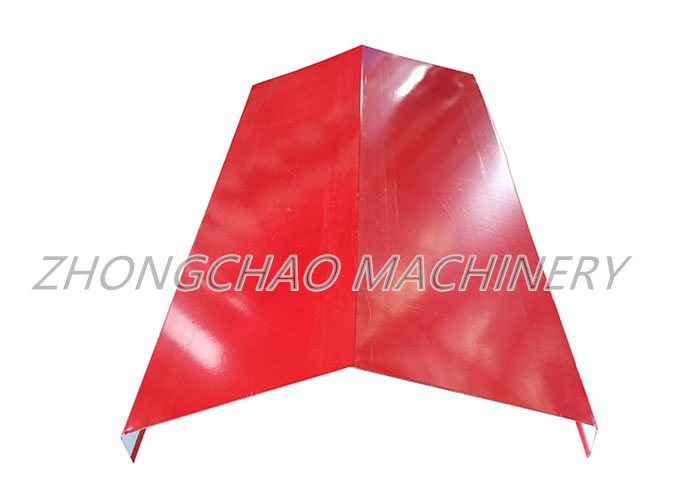

Color steel roof ridge cap roll forming machine manufacture

1. Usage And Introduction Of This Production Line

The ridge cap forming machine has characters of high spped ,high production, good performance, low labor and save cost. All the above characters are the best selections for producing the metal sheet cold roll form products.

The forming rollers is the key of roll forming machine. We use CAD to design and manufacture the rollers. After CNC lathe, the forming rollers will be harden by vacuum heat treatment and finished the profiles again. These processes make the more accurate forming rollers ,avoid the deformation during heat treatment and ensure the rollers’ preciseness and wear-resisting ability.

The components of the roll forming machine line includes:

2. The roll forming machine parameters

Botou Shitong Cold Roll Forming Machinery Manufacturing Co.,Ltd. is a professional manufacturer and exporter that are concerned with the design, development and manufacture of cold roll forming machines. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

Our equipment keeps a foothold in the domestic market, at the same time, we've developed international market in many countries. Having exported our equipment to Europe, Africa, South America, Russia, Burma, Pakistan, Sri Lanka, Uzbekistan and other countries and regions, we have received high praise from the foreign customers.

4. Our service of the roll forming machine production line

(1) Once you paid the deposit, we will start the production as soon as possible. When the machine is finished, you can come to check the machine, we will arrange your accommodation and relative schedule. If you don't come, we can test the machine and send you test video. It's no problem.

(2) Our machines have one year guarantee, within one year, if the machine parts has some problem, we will be in charge of the repairing or replace. Also we will deliver the customer some spare parts together with the machine when loading the machine.

5. FAQ

5.1: We bought your roll forming machine line, but we couldn't install and debug it?

5.3: - Can you finish the machine during the delivery time?

A: We will finish the machine in time according to determined lead time.

5.4:- Can you provide some spare parts?

A:Yes, of course. The quick-wear parts are sent to you together with the machine.

6. Roll forming machine pictures:

Hydraulic decoiler ( 5 Tons )

1 unit

Main Roll Forming Machine

1 unit

Cutting Device

1 unit

Electrical System with PLC Control

1 unit

Hydraulic station

2 unit

Auto stacker

1 unit

No.

Item

Specification

1

Can Formed Material

GI,AI

2

Equipment operation

Automatic

3

Voltage

380V 60Hz 3Phase or as your requirement

4

Thickness of sheet (mm)

0.3-0.7mm

5

Material width(mm)

As your requirement

6

Cover Width of the sheet after formed

as your drawing

7

The size of the roll forming machine

5500mmx1200mmx1400mm

8

Speed

12-15m/min

9

Diameter of shaft

40mm

10

Weight of the Machine

2200-2500KGS

11

Material of rollers

Cr12 steel quenched and chromed

12

Motor brand

Siemens or Guomao

13

PLC

Siemens or Delta or Mitsubushi

14

Total power (kw)

8kw

15

Power of hydraulic system

4kw

16

Power of main molding core

4kw

17

Transmission

Chain with gears

A: Don't worry about that, when finished the machine, we will send you the manual book which shows you how to use the machine; if you still don't know, we can record a video to teach you how to operate the machine.

5.2: About the after service, if the machine has problem out of guarantee?

A: All the machines are one guaranteed, life maintenance. It means if you order our machine, you will be our customer for lifetime, you can ask us anytime about the machine issues.

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series