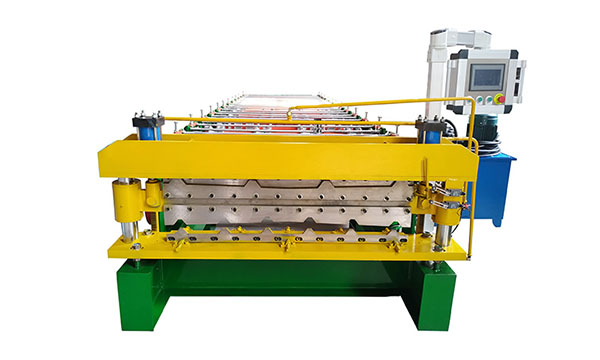

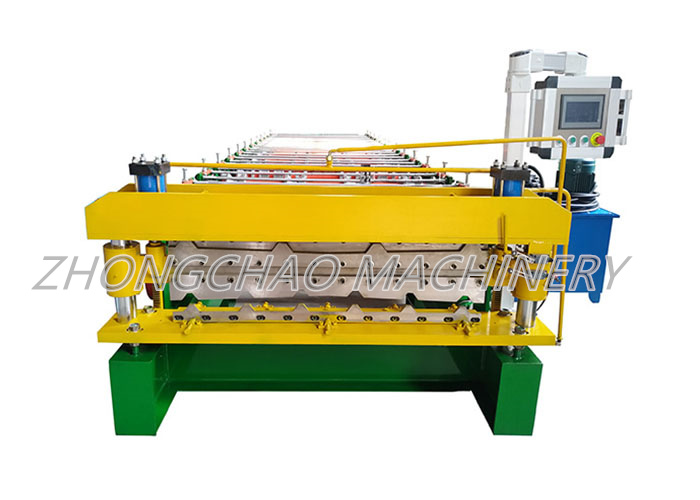

Color Steel Deck Roof Sheet Making Double Layer Roll Forming Machine For Ppgl

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

1.glazed roof tile double layer roof sheet roll forming machine and uncoiler are nude packing (If you need, we can also packed it with water-proof plastic)

2. PLC control system and motor pump are packed with water proof paper,spare parts in carton box.

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

2. Delivery time: Within 35 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.

FAQ

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3)Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit

We are Gold supplier with BV assessment and CE certificate.

4)Q: What can you do if the machine broken?

A: Our machine's warranty period is 18months,if the broken parts can't repair

we can send the new parts replace the broken parts free,but you need pay the express cost yourself if after warranty period ,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

5) Q: Can you be responsible for transport?

A: Yes,please tell me the destination port or address we have rich experience in transport.

Product

steel double layer roll forming machine

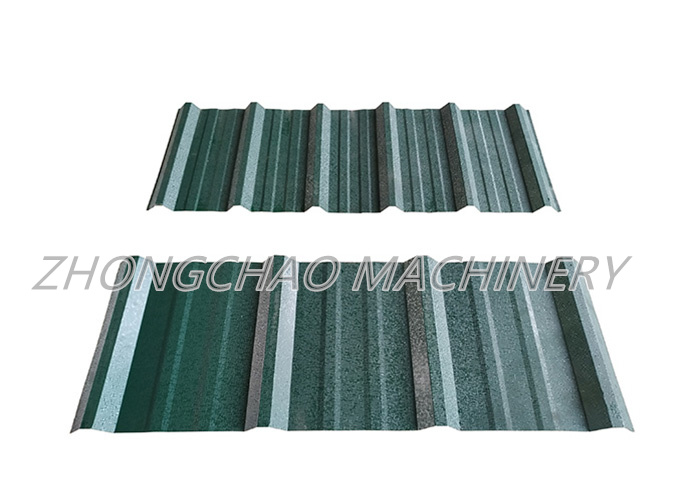

Corrugated & trapezoidal (Our engineer and designer team service for you!! )free!!!

Base material

GI/GL,PPGI/PPGL,Aluminum coil

Thickness

0.3mm-0.8mm

Effective Width

600-1250mm (according to your need)

Roller material

45# steel

Color

All colors (standard international color)or customers samples’ color

Brand

HX

Control System

Famous Brand PLC

Power

4KW-5.5KW

Frame

350Hsteel

Cutting drive

Hydraulic drive,electric motor

Cutting&Hydraulic type

Type:double guide pillar hydraulic cutting.Hydraulic pump station :4kw Blade:Cr12mov Hrc:58-62

Feature

Building metallic materials have excellent performance of decoration, corrosion resistance etc,easy to operate, energy saving,flexible manufacturing,high productivity, eco-friendly.

3.One set of machine needs a 40' container to shipping.

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series