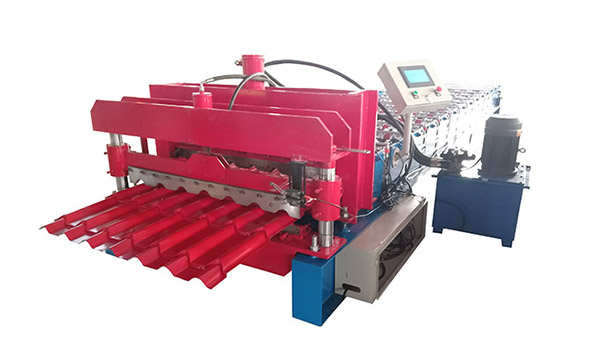

CE Hydraulic Tile Making Machine Glazed Tile Forming Machine

main parameters:

Quenched and tempered treatment,

hard chrome coated 0.05-0.07mm

It has the advantage of slowing down before cutting, to ensure the

length accuracy(±1mm, much better than industrial

standard ±3mm).

working process:

Decoiling--Roll Forming--Cutting to length--Product to output table

company introduction:

Established in 1998.botou shitong cold bending machinery co,.ltd is a professional manufacturer of roll forming machines.We have the engineers with rich experience on design of roll forming machines, and also have a professional team on production and service, we pay more attention to develop our technology to meet the market requirement and engaged in supplying the customers with high efficiency, easy operation and best price equipment. We export our roll forming machines to a lot of countries(India, Iran, Ireland, Dubai, Mexico, Iraq ,Zambia, and so on..) At present, our main products include Roof / Wall Panel Machines, Joint-Hidden Roof Panel Machines, C/Z Purlin Machines, Decking Machines, Pu Foaming Machines, Shutter Door Machines, Hat/ Keel Machines and so on. The products are more than 80 types. PLC computer control system is widely used in the equipment. Technical performance and precision have been up to the advanced level . Due to our professional services with high efficiency, good quality and low cost, we have achieved good fame among clients.If you are interested in our products, please feel free to contact us for more information. We are looking forward to cooperating with you in future.

No.

Metal Roof Panel Roll Forming Machine

1

Suitable material

PPGI/Aluminium sheet/galvanized sheet/galvalume sheet

2

Thickness of coil sheet

0.2-0.8mm

3

Coil width

914~1250mm

4

Cutting method

Hydraulic guide pillar

5

Material of main frame

350H steel

6

Diameter of Soild shaft

75mm, high grade 45# steel

7

Roller material

8

Thickness of middle plate

16mm

9

Forming station

18 stands

10

Drive type

By chain(1.3 inches) link bearing model 6210

11

Power of main motor

5.5kw with Cycloidal reducer

12

Power of pump station

4kw

13

Forming speed

About 8-12m/min

14

Hydraulic cutting

Controlled by PLC

15

PLC brand

DELTA(TAIWAN)/Panasonic (Japan)

16

Material of cutting blades

Cr 12, quenching 58-62℃

17

Frequency converter

18

Switch

CHNT

19

Transducer

DELTA(TAIWAN)

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series