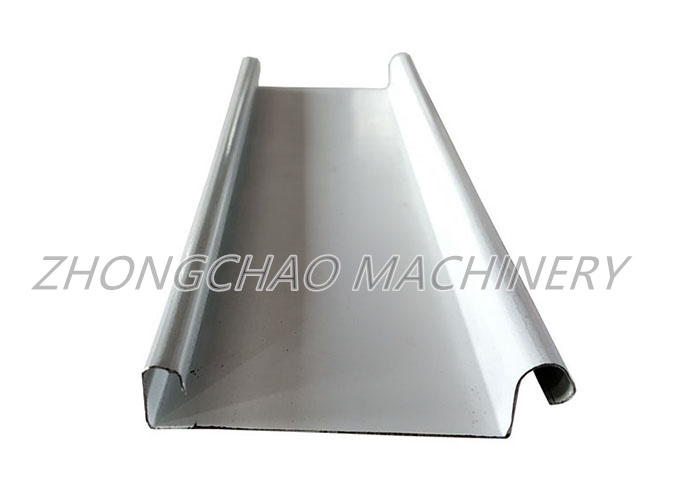

Automatic metal steel roller shutter door frame roll forming machine

Product description:

1.Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

FAQ

1Q: Are you a factory or a trading company?

1A: We are a factory.

2Q: Where is your factory?

2A: Our factory is located in Botou City, Hebei Province, China. Warm welcome to you

Come visit us!

3Q: If I want to customize the machine, what should I provide?

3A: We need outline drawing, material information: feed width (1220mm?),

Thickness (0.35-0.6mm?), steel coil yield strength (G550Mpa?), voltage and your special requirements

Require.

4Q: What should I do when I first learned about the roll forming machine?

4A: Contact us immediately, we provide free consultant pre-sale services.

5Q: Can you make a machine based on my design or prototype?

5A: Yes. We have professional designers to formulate the most suitable design and

The production plan of the machine you want to book with us

6Q: How can I believe that your machine has a test run before it is shipped?

6A: 1) We recorded a test video for your reference.

2) You are welcome to visit us and test the machine in our factory.

7Q: Do you provide overseas installation and training?

7A: Overseas machine installation and worker training services are optional.

8Q: How about your after-sales support?

8A: We provide online technical support and overseas services for skilled technicians.

9Q: Shelf life:

9A: Within one year from the date of completion of commissioning. Guaranteed to cover all

In addition to wearing parts, electrical, mechanical and hydraulic components in the line.

Our Color Shutter Door Machine Advantage

Suitable Material

Material

Galvanized Sheet

Width

161 mm

Thickness

0.7-0.8 mm

Material of rollers

High grade 45# forged steel, surface hard chromium plating

Rows of rollers

12 stations

Material of shafts

High grade 45# forged steel

Diameter of shafts

50mm

Material of blade

Cr12 Heat Treatment

Speed

8-12 m/min

Total power

4 kw

Voltage

380V 50HZ 3Phase

Appearance size (About)

4600mm*800mm*1500mm

Electronic control system

PLC +Touch Screen

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series