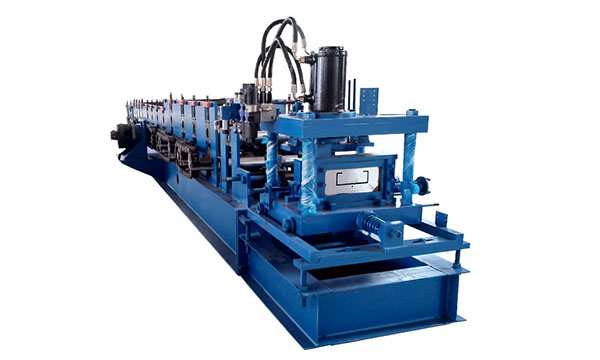

Automatic 80 300mm Operating High Speed C Purling Steel Roll Forming Machine

| Voltage | 380V Or As Customize | Weight | 11Ton |

| Warranty | 2 Years | Production Capacity | 8-12m/mins |

| Name | Lip Channel Roll Forming Machine | Roller Material | Cr12 mov |

| High Light | Purlin making machine, purlin roll former | ||

Quick Details

| Warranty | 2 Years |

| Power(W) | 15kw |

| Certification | CE/ISO9001, ISO |

| After-Sales Service Provided | Free spare parts, Field installation, commissioning and training |

| Applicable Industries | Manufacturing Plant |

|

Work Pressure |

Normal Pressures |

| Production Capacity | 8-12m/min |

| Voltage | 380V/50HZ 3Phase(as Customer’s Request) |

| Dimension(L*W*H) | 8m*1.1m*1.2m |

| Weight: | 7.5T |

| Key Selling Points | Automatic |

| Color | Customized |

| Any | Color |

| Product Name | C Shaped Roll Forming Machine |

Machine Paramete

| Item Name | Specification |

| Effective Width | 80-300 mm |

| Thickness of Feeding Material | 1-3 mm coil sheet |

| Roller Station | 8-12 stations |

| Shaft Diameter | 80 mm |

| Productivity | 8-12 m/min |

| Rollers’ Material | 45# steel forge |

| Shaft Material | 45# steel |

| Weight | 8tons |

| Length | 8 m |

| Voltage | 380V 50Hz 3phases |

| Control | PLC |

| Decoiler | 5 tons |

| Motor | 11kw |

| Driving Way | Chain transmission |

| Chain Size | 1-2 inch |

| Cutting System | Hydraulic cutte |

Usage And Introduction of This Production Line

Our own tooling center is equipped with CNC turning-lathes, Grinding machine for roller shaft, Heavy planing machine,etc, which allow us to complete the majority of our processing procedures on-site. So we can better control the machine quality and delivery time of machines.

Our range of products: sandwich panel production line, roof tile forming machine, cladding forming machine, metal decking forming machines,etc. We also can supply steel coils,EPS sandwich panels,PU sandwich panels to suit diverse requirements of our global customers.

After-Sales Service

(2) Our machines have one year guarantee, within one year, if the machine parts has some problem, we will be in charge of the repairing or replace. Also we will deliver the customer some spare parts together with the machine when loading the machine.

(3) If the buyer need overseas debug, we can also send technician to your factory, the customer should undertake all related cost including the accommodation and round-trip ticket of technician: 100 USD/day . The buyer should make sure the safety of technician.

The PLC Control System of The Production Line

It adopts industrial computer to control.

The target piece’s length is adjustable and digit of it can be adjusted.

Computed mode has two Modes: automatic one and manual one. The system is easy to operate and use.

It contains programmer, transformer for the electronic machines and kits of every part.

Language screen: Chinese, English or Russian language.

Roll Forming Machine Pictures

Tel:+86-15930785588

Whatsapp:+86-15930785588

Fax:+86-15930785588

Email:robin@chinasupercompany.com

Address:West Side Of No. 1 Road, Economic Development Zone, Botou, Hebei, China (Mainland)

Please feel free to give your inquiry in the form below.We will reply you within 24 hours

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Double Deck Roll Forming Machine

- Three Layer Roll Forming Machine

- Gutter-Roll-Forming-Machine

- Bending and Cutting machine

- Sandwich Panel Roll Forming Machine

- Door Frame Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Standing Seam Roll forming Machine

- Floor Deck Roll Forming Machine

- Roller Shutter Door Roll Forming Machine

- C-Z-U Purlin Roll Forming Machine

- Downspout Roll Forming Machine

- Guardrail Sheet Roll Forming Machine

- Light Keel/ Stud And Track Roll Forming Machine

- Ridge Cap Roll Forming Machine

- Accessory Series